AL-KO pushes green solutions for caravanning industry

AL-KO Vehicle Technologies is promising to continue its push towards holistic green solutions for the caravanning industry when it exhibits at the upcoming Caravan Salon fair this year. AL-KO says it has optimised the entire system of its products for the show in a bid to make travelling in caravans and motorhomes more environmentally friendly – with a real focus on helping electric vehicles take a more prominent role in the industry.

“We have designed new vehicle concepts and system carrier platforms that combine leisure and commercial vehicles with electromobility,” explained Harald Hiller, president and CEO of the AL-KO Vehicle Technology Group.

A trail of green

Easier said than done – one of the biggest problems with e-mobility is the short range of many of the current vehicles – especially in caravans where the additional heavy batteries increase driving resistance, which can only be countered with bigger but heavier still batteries. Longer range can be achieved in this way but at the expense of much higher energy consumption, which is bad for the environment.

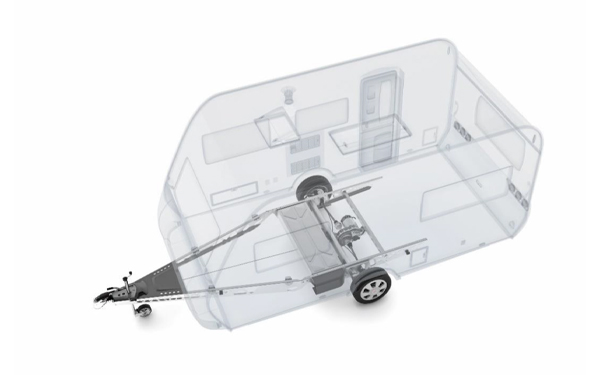

“Our approach is therefore to decisively reduce driving resistance by consistent lightweight construction, an intelligently controlled braking system in the trailer and optimized aerodynamics”, says Dr. Frank Sager, senior vice president of research and development at AL-KO Vehicle Technology Group.

In AL-KO’s testing using the Tesla Model X on a demanding rout from Bavaria to South Tyrol last winter, the vehicle achieved 265km with no trailer – but adding a normal caravan to it halved the distance it was able to achieve. AL-KO’s new Green Trailer Platform with e-drive, optimised braking system and improved aerodynamics managed to increase this range again by almost 40 per cent.

Dr Sager said: “We can assume that the train range in summer conditions can reach around 75 per cent of the range of the solo vehicle – a practical offer for most caravanners, and that at a reasonable cost, with a small, efficient e-drive, that at the same time takes over the task of manoeuvring.

“We are also thinking intensively about retrofit solutions. We cannot yet name a series date because the approval regulations have to be accommodated. We cannot influence the timeline for that, but we hope that there will be positive interest and political support for our sustainable approach. We want to provide comfortable and affordable solutions at an early stage.”

Forward-thinking developments

“Using the holistic green caravanning approach — consisting of lightweight construction, electrification, aerodynamics and sustainable materials — we are optimizing trailer trips’ CO2 emissions and reducing primary energy and raw materials consumption,” says Dr. Sager.

For example, further developing the VARIO X lightweight chassis ensures that trailers are up to 30 kg lighter and additional CO2 emissions can be saved. AL-KO manufactures around 60,000 caravan chassis annually, more and more using the bionic VARIO X design.

Aerodynamics as an effective lever to reduce the CO2 footprint and increase the range is an essential factor for the bodywork manufacturer to grasp. Dr. Sager said: “Our research shows that it is possible to improve the overall air resistance of the trailer by 30 per cent, especially by optimizing the front and rear areas of the caravan as well as in our area on the underbody. Close cooperation between the caravan manufacturer and us, even at the development stage, is decisive for success. To this end we enter into cooperation with renowned caravan manufacturers, universities and suppliers.”

Sustainable motorhome platforms

AL-KO already has a reputation as being a leader in motorhome chassis, with 35 years of innovation under its belt, but the company believes the evolution will never stop. The evidence of that can be seen in the new AL-KO motorhome chassis (AMC), which are 30 to 40kg lighter than their original iterations and in the last four years alone have saved 7 per cent of weight through continuous optimisation. The low-frame chassis also aim to help make integrated motorhomes have a smaller front surface to improve aerodynamics, without reducing or restricting floor space within the leisure vehicle. The next evolutionary stage of the AL-KO motorhome chassis is imminent. It enables even lower vehicle heights. Consistently implemented, this leads to a reduced vehicle frontal surface and further improves the aerodynamics. Using the aerodynamic potential of the chassis, AL-KO provides the market with an effective adjustment for reducing energy and thus saving CO2 emissions. The first on-road prototypes of the Hybrid Power Chassis also benefit from years of AL-KO research and development and its successful development partnership with Huber Automotive AG. Likewise, the AMC chassis is also used here. The electrified rear axle with a peak power of 124 kW can be switched on as required. The battery capacity is designed for an all-electric range of between 60 and 100 km. Other advantages of the diesel-electric HPC concept are the on-demand 4WD driving mode and the self- sufficiency of battery use, for example for the power supply to the motorhome body.

You can see AL-KO on stand A03/01-02 in Hall 14 at the Caravan Salon Fair in Düsseldorf.

- Log in or register to post comments